Selecting a barcode printer

One of the most important aspects of barcode printing is choosing the right barcode printer. Thermal based barcode printers provide a very economical way to create high quality labels, tags, wristbands, receipts, and tickets. Compared to other printing technologies, thermal-based options require less maintenance, have less expensive media, and print faster while maintaining excellent print quality.

Since these types of printers are different from your typical laser or inkjet printers, it can be a challenge to know which one will fit your business best. The first step in finding the right printer is to identify your specific need(s).

Print Resolution

Barcodes require clarity in order to be scanned and read. The barcode symbology is comprised of a series of bar of different widths. When buying a thermal barcode label printer, you should consider the print resolution, which can range from 203 dots per inch (dpi), 300 dpi or even 600 dpi for special applications. The higher the number of dots per inch, the finer the resolution. A barcode printed at 200 dpi is not going to be as clear as one printed at 300 dpi, which imprints over 200 percent more dpi. The difference in cost between 203 and 300 dpi is nominal. If your barcodes are large enough, 203 dpi is fine. But if you’re using a thermal barcode label printer to produce high density bar codes, 2D barcodes, fine fonts, or detailed graphics, consider choosing a higher resolution printer.

Print Volume

Some barcode printers are engineered to handle a heavy volume of label output, while others are best suited for small runs. If you’re going to use a thermal barcode label printer for occasional, on-demand printing, the print speed is not an issue, but you certainly don’t want to slow down production because your printer can’t keep up with a higher volume.

Label Width

Label printers are classified based on label widths. There are 3 main label widths that you have to consider before choosing. 4`` 6`` or 8``. Larger printer width printers can take smaller labels but not the other way around.

Connectivity

Will your thermal barcode label printer be kept in one place or do you need a mobile printer? If it’s going to be wired, do you need to connect it via Ethernet, USB, serial, or parallel ports? Be sure the printer you choose is equipped to connect with your current network.

Compatibility

The thermal barcode label printer you choose must be compatible with your enterprise. If you’re running on an ERP or SAP, check to make sure the printers you’re considering have the interconnectivity and drivers/device types to run with those systems.

Standard is a general purpose resin ribbon with outstanding scratch resistance. Resistance to moisture and sunlight make Standard Resin an excellent choice for outdoor and heavy abrasion applications. Standard Resin is a competitively priced alternative to other brand resin ribbons.

Knowing how you’ll be using a printer will help you decide what type, print method, and other features you’ll need. Understanding and going through the following features will help you determine the best printer for your needs.

Printer Types

The first question when finding the right printer is deciding what type of printing you'll be doing. Printers can be divided into 4 category types depending on how mobile they are and if they can make labels, receipts, tickets, or wristbands.Standard is a general purpose resin ribbon with outstanding scratch resistance. Resistance to moisture and sunlight make Standard Resin an excellent choice for outdoor and heavy abrasion applications. Standard Resin is a competitively priced alternative to other brand resin ribbons.

Thermal Label Printers

They may be called ``label`` printers but these are by far the most flexible printers since they can print on any media that will fit inside the printer. If you are primarily making labels and will also need to make tags or wristbands, these printers are your all-in- one solution. All thermal label printers are not the same though. The biggest difference between them is how heavy of a print volume they can handle. These printers come in many forms.

Desktop

This type of printer is made for small volume applications that are making fewer than 500 labels per week on average. Desktop printers are perfect for asset labeling in an office or light printing duties at a retail store. Printers like the Zebra GK420 still produce the same quality and wide range of media as bigger printers, just at a smaller volume.

Industrial

Even though standard label printers can also create wristbands, a dedicated wristband printer offers several advantages and a lower overall cost. For applications that are making wristbands every day like hospitals, theme parks, and concert venues, a dedicated wristband printer is the perfect fit. These printers also have a higher print resolution standard for clear, accurate printing of images or logos.

Mobile

Mobile printers are similar to thermal label printers but provide freedom from any cable connections to a PC. Mobile printers do have a few limitations due to their small size. They are not made for very high volumes, have limited roll capacity, and have smaller print widths, usually 2, 3, or 4; max. However, if you need to make labels or receipts on the move, a mobile printer will provide you high quality print in a compact package that fits on your hip. These printers are perfect for delivery drivers or sales agents to create receipts in the field or a warehouse worker that needs to make labels on the spot. Since these printers are not tied to a fixed PC, you normally communicate to them wirelessly through Bluetooth or Wi-Fi.

Wristband

Even though standard label printers can also create wristbands, a dedicated wristband printer offers several advantages and a lower overall cost. For applications that are making wristbands every day like hospitals, theme parks, and concert venues, a dedicated wristband printer is the perfect fit. While other printers have their media on a roll, wristband printers have cartridges that simply drop into place to keep you printing with almost no downtime.

Ticket

Ticket printers are another specialized thermal printer that excels at printing on thicker paper for ticketing applications. If you are making tickets for concerts, festivals, or any other type of event, a dedicated printer will help you make them faster with less hassle. Since most tickets come in a fan-folded stack instead of rolls, these printers have a taller case to accommodate more stacked media. They can also still use roll media but with a larger stack of tickets you will spend less time reloading the printer. These printers also have an opening on the back of the case to easily feed ticket stock externally.

Print Method - Direct Thermal vs. Thermal Transfer

Once you know what type of thermal printer you need, the next big concern is what print method you'll use. Thermal printers are capable of printing in 2 different ways - direct thermal (DT) and thermal transfer (TT). Depending on how long you need the label to last and the material it's made of, one of the two methods will be more effective for your application.

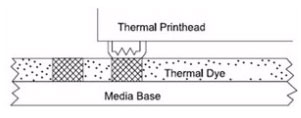

Direct Thermal

Direct thermal printers utilize heat- sensitive media that blackens as it passes under the printhead. Because they print without a ribbon, direct thermal printers are noted for their simplicity. Direct thermal printed labels typically have a considerable shelf life but are not well suited for environments that expose them to heat, long periods of direct sunlight or abrasion. Because of this, thermal labels, tags or ticket stock are often top coated to resist these elements. Direct thermal printing produces sharp print quality with good scan ability using only one consumable. For any short term labeling application, like shipping labels, direct thermal is the most efficient print method.

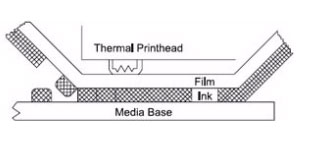

Thermal Transfer

Thermal transfer printers use a ribbon, similar to a fax machine, which is melted onto the label by the printhead. This method makes it easy to use label materials beyond paper including synthetic materials, like polypropylene and polyester, for outdoor and harsh environments. Beyond the added durability, thermal transfer printed media also has a very long shelf life making it perfect for product labels, asset tags, and outdoor wristbands. Since you are using a ribbon, you also have the option to change the color of your print beyond just black. With the right combination of labels and ribbon, you can make a label for any environment or application. Though it does cost a little more to print thermal transfer media, the added benefits ensure your label or tag is readable throughout its life without ever needing to reprint. With all the options available for barcode printers today, it can be a challenge to find the right device for your business. Determining the type of printing, overall volume, and what features you need from above will make deciding on a printer easy. If you are still having difficulty or have additional questions, feel free to call we're happy to help you find the right printer for your needs.

Finding the Right Printer

With all the options available for barcode printers today, it can be a challenge to find the right device for your business. Determining the type of printing, overall volume, and what features you need from above will make deciding on a printer easy. If you are still having difficulty or have additional questions, feel free to call our experts - we're happy to help you find the right printer for your needs.